B2B

Our offering of custom fabricated 3D glass engraving is intended mainly for B2B customers. We are the partner of choice for companies, craftspersons and retailers seeking outstanding, visually appealing engraving products of high quality in larger quantities.

End consumers may purchase products from the collections through online shops that carry our goods. We offer custom fabrication for end consumers in exceptional cases. Please contact us in this regard with no commitment. We are happy to find the most favourable option for you depending on the desired motif and circumstances.

2D glass engraving based on photos or pictures is gladly offered as individually fabricated items for B2B customers and end consumers.

Services

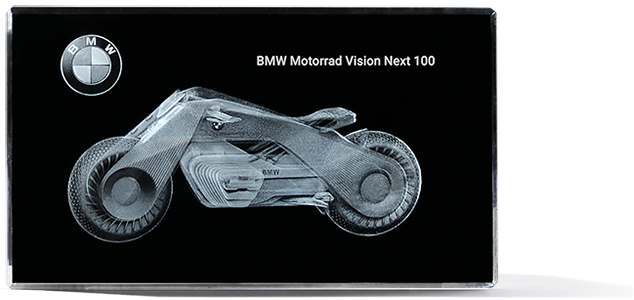

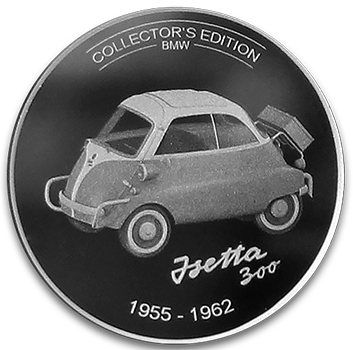

Glass engraving: We fabricate 2D and 3D interior glass engravings (no surface engraving). 2D engravings are produced based on image data, and company logos are usually 2D engravings as well. 3D glass engraving is the crowning discipline and our speciality. Producing the 3D point clouds for free-standing objects such as vehicles, instruments, sculptures or similar requires 3D data. 3D scenes such as those depicted in our Architecture collection are special cases and the required data basis is highly dependent on the motif. We are happy to discuss your ideas without commitment.

3D data: The 3D data for the lasering object are generally provided by you since this considerably reduces the costs. If this is not possible, we will gladly attempt to procure the 3D data directly or to model the motifs ourselves, provided we currently have the capacities available.

Image editing: For 2D engravings, we convert the images provided by you to laser data the way they are delivered by you (e.g. a person is lasered with the image background). We can provide image editing services such as background removal or retouching on request.

Outer packaging: Our glass blocks and keychain pendants are delivered in sturdy standard gift boxes. In case of custom fabrication in large quantities, we are happy to advise you regarding individual, decorative outer packaging or to handle procurement.

phenolux 3D vs. standard 3D

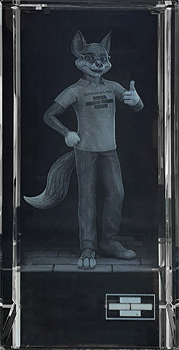

Designing the point cloud using our phenolux method makes a high quality 3D glass engraving into glass of outstanding visual appeal possible, representing each 3D model down to the details and in finely balanced shades of grey.

We invest about 5-7 working days in this depending on the motif, which naturally incurs corresponding design costs.

The standard method to prepare a point cloud is less elaborate and therefore incurs lower one-time costs. This method is also more suitable for some motifs, for example in case of technical machinery or vehicle engines that have a low-contrast surface and where the 3D model simultaneously consists of countless small individual objects.

When you submit your 3D data, we check with no commitment which method is suitable for preparing the point cloud (laser file).

BBCrystal vs. standard glass

The special BBCrystal laser glass brings out any lasered motif to its best advantage. The patented crystal glass is available in two sizes (80x50x50mm and 140x80x80mm, landscape or portrait format), and always the right choice for 3D crystal engraving products in the premium market segment or for special occasions.

Naturally we also laser standard glass (transparent) in various sizes and formats. Keychain pendants, drinking glasses and collectible coins fall into this category. Please talk to us if you have special wishes regarding the glass shape and size.